DESCRIPTION

Mechanical connectors for joining reinforcements, of equal or different diameter, to guarantee transmission of forces from one bar to the next.

They have, at least, the same strength as the thinner of the bars spliced and must not slip more than 0.1 mm under service stresses.

When traction is tested, breakage must occur outside the mechanical splice, which has values greater or equal to those of the characteristics of the bars.

CHARACTERISTICS

Advantages of the use of mechanical splices

Alternative to joint using overlap or welding

They make the mechanical joint between reinforcements:

When splice by overlap is impractical due to the lack of space in strongly assembled parts.

In construction joints, with no space, no space for the insufficient overlap length.

In correction of errors, execution, such as insufficient overlap lengths.

Where the fixed bar is concreted, protecting the thread to then put the sleeve on.

They simplify the design and construction of the structure.

Facilitates concreting by eliminating the defects and problems of vibration in densely assembled areas.

When reinforcements are joined with a diameter of over 32 mm with overlap, the correct behaviour of the joint should be justified with special studies for each use as transfer of stresses from one bar to another, in splicing by overlap, produces radial traction that is very difficult to control. If the joint is made using a mechanical splice, this does not have to be justified using special studies.

This is a fast and simple option for joining reinforcements on site.

In repairs of reinforced concrete structures

In repairs of reinforced concrete structures, when it is necessary to cut reinforcements, the couplers are suitable for recovering the

continuity between the reinforcements.

In prefabrications and extensions of structures

The joint is made simply and quickly in joints of prefabricated elements.

They simplify the connection of connected structures or future extensions in adjacent buildings.

Typology of mechanical splices

There are several types of mechanical splices depending on the nature of the joint:

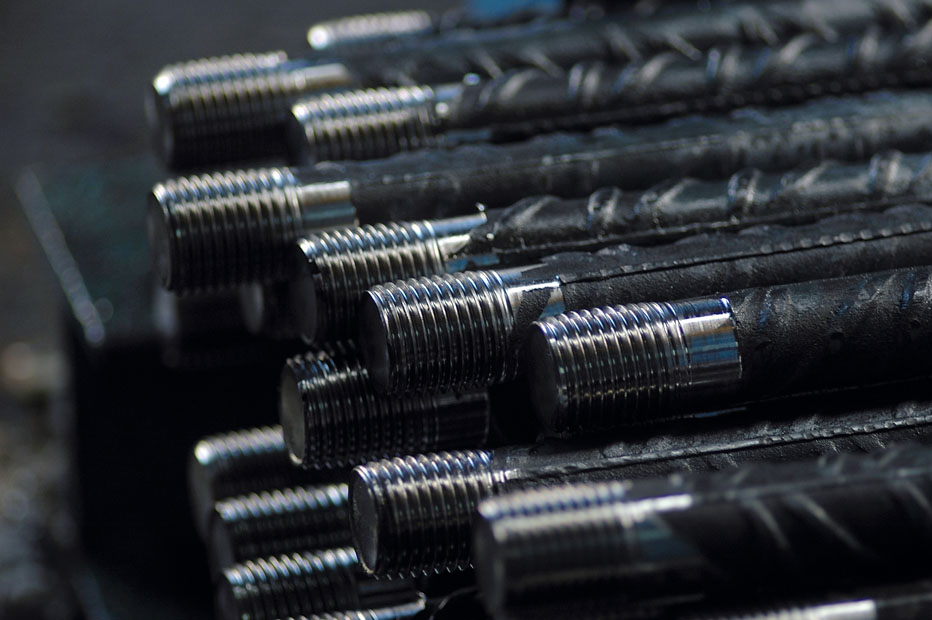

Threaded Mechanical Splice:

The main one is based on stressing the ends of the bars with a machine that applies pressure. The bars are threaded on the thickened diameter area and coupled into the sleeve.

Screwed Mechanical Splice:

This consists of connecting the bars, without having to prepare them or turn them beforehand, using a tube with some serrated gripping notches and tightening screws. When the required pressure is obtained on the bars the heads of these screws break off, with the body of the screw nailed into the bars preventing them from moving inside the tube.