INDUSTRIALISED STEEL

The development of societies requires progress in construction projects that provide a significant improvement in values required by users and all the players involved in the construction process. These values reflect different motivations and needs

Prevention of occupational risks and improvement of the working conditions of the people

Reduction in delivery times

Optimisation of the project’s overall costs

Quality standard assurance: durability and safety of the structures

Control and traceability of materials

Project documentation

Respect for the environment

ERSI Group was created with the aim of structuring these technical proposals with new products and construction methods.

INDUSTRIAL REINFORCEMENTS FOR CONCRETE:

Rationalisation of reinforcements that optimises the design of the project with equivalent reinforced concrete proposals

The cost of the structure does not exceed 15% or 20% of the total amount of the projects. However, it represents the 50% of the time of its construction. Hence the importance of analysing the implementation methods we offer.

Together with the ERSI Group Engineering Department:

We analyse traditional reinforcement drawings provided by the customer.

We propose changes for the use of reinforcements manufactured in an industrialised way.

We guarantee the following advantages:

We provide corporate and technical support from the headquarters.

They are easy to place in the formwork.

They offer economic advantages.

They offer technical advantages.

They improve safety.

They protect the environment.

This rationalisation of the reinforcements allows optimising different aspects:

Technical: We apply reinforced concrete forms and schemes that make it possible to use industrialised reinforcements and achieve maximum standardisation of the reinforcements ensuring the safety of the structures.

Construction: We reduce labour in the manufacture and placing by constructing viable reinforcements, replacing complex structures with elements with easy on-site installation, apply a regular spreading of the reinforced concrete with the fewest number of bars with the largest diameters and facilitate the placing of the prefabricated elements.

Economic: We obtain the use of the most adequate mean diameter according to economic performance. We save steel using new construction details and new working techniques. Use of industrialised reinforcements that optimise total costs of the passive reinforcement steel from reduction in labour in manufacturing and placing.

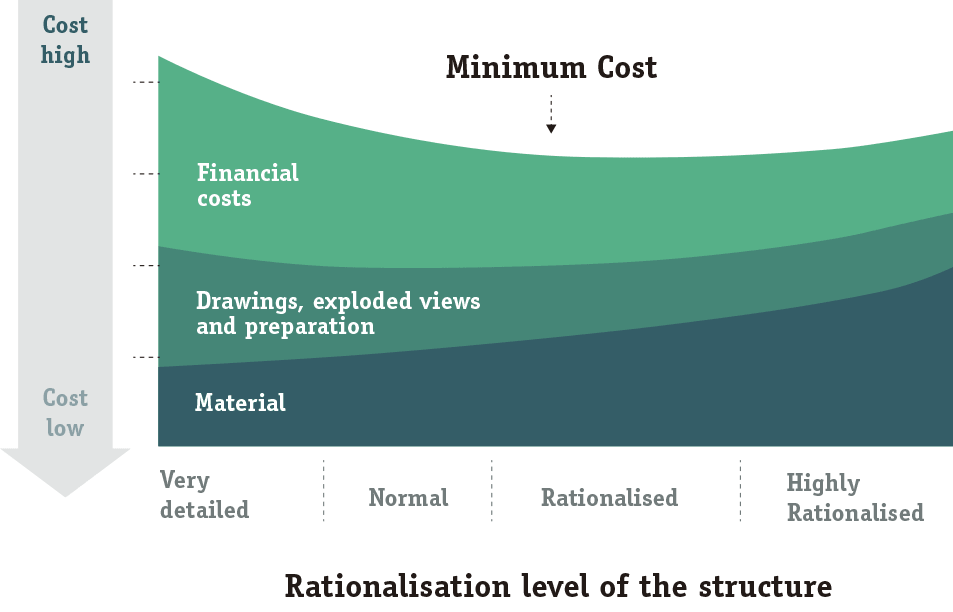

In the graph below we can see how industrialisation of the reinforcements implies a slightly higher amount of steel compared to the traditional ones, with a reduction in the total cost of the structure and a shortening of the construction time.

Innovative products adapted to new construction methods

Certified commercial steel

ERSI Group manufactures with commercial steel products certified internationally. The quality certificates are included in its documentation.

Manufacturing in industrial plant:

Industrial manufacture of reinforcements for concrete incorporates the most advanced methods and manufacturing processes in an industrial plant, to ensure compliance with the highest standards of quality and avoid the problems suffered in small-scale, on site manufacture.

Machinery with advanced technology

Minimum tolerances

Bending mandrels corresponding to each diameter

Welded joints

Industrial Reinforcements adapted to each type of project and application

Manufactured reinforcements.

Prefabricated reinforcement.

Electrowelded panels.

Standard reinforcements.

Specific accessories.

Quality plan by processes and trials

Traceability of products using bar codes on identification labels throughout the production and dispatch processes.

Economic advantages

Project execution cost

Reduction of 3% to 19% of the total cost of the structural element.

Industrial reinforcements that allow for a significant decrease of action increase coefficients, which represents significant savings in the construction (from 3 to 19% of the total cost of the structural element)

Reduction of human resources and suppression of material means on site to manufacture the reinforcements:

Staff necessary for the manufacturing workshop (machines, stock of raw material and finished products).

Space necessary for the manufacturing workshop (machines, stock of raw material and finished products).

Lifting facilities (cranes for unloading raw materials from lorries and transporting reinforcements in the workshop).

Consumable materials for the workshop and safety accessories (electricity, water, lubricants, etc.).

Increased consumption of raw materials, due to the automatic non-optimisation of cutting (poor utilisation of the crop cuts and losses from scrap).

Elimination of the stock in the works of the commercial steel for the reinforcements (preventing theft, deterioration of the material, use for other purposes, immobilised assets).

Other benefits: in addition, our prefabricated industrial reinforcements, special panels, made-to-measure panels and standard reinforcements also obtain:

Reduction of deadlines for implementation of the structure with new construction methods that reduce reinforced concrete on site.

Reduction in delivery times. ‘In conventional construction, the implementation of the structure represents 50% of the total time of the carrying out of a building (Prof. J. Calavera)'.

Reduction of downtime of use of equipment and works means (formwork, cranes and other), during the on-site reinforcement of the elements.

Cost of non-quality during the life of the structure

Non-quality is the decisive cause of the pathologies that occur during the life of the concrete structures, to be distributed (according to AOCTI)4 in the following way:

40 - 50% are due to the project itself. Rationalisation of the projects (on including construction details and proposing the use of industrialised reinforcements) makes them more viable, easier to carry out and control.

25 - 35% are due to their implementation. Manufacture of reinforcements in fixed industrial plants guarantees a high level of quality in the implementation of the reinforcements and, therefore, prevents mistakes in the construction of the structures due to the reinforcements.

10 - 15% are due to faults in the materials used. The use of high-performance commercial steels ensures compliance with the technical requirements stipulated in the standard, as well as correct manufacturing.

5 - 10% are due to improper use and maintenance. A defined and well-located record of the documentation relating to the reinforcements allows immediate intervention in the event of problems.

In the buildings, risk reduction can provide significant savings in the Guarantee and in their incidents.

Technical advantages

Maximum flexibility for adaptation to the project:

The combination of the various ERSI Group products allows carrying out any structure:

Manufactured industrial reinforcements, assembled on site and subsequent placing.

Prefabricated reinforcement.

Special panels: large series specially manufactured for a particular project.

Made-to-measure panels: small series made to measure for a constructive element.

Both the diameters used and the separation between bars and anchor and overlap lengths are adapted to the specific case for which they are intended.

Great stiffness:

Prefabricated industrial reinforcements, special panels, made-to-measure panels and standard reinforcements.

What do our welded joints guarantee?

The separation between the bars as specified in the project, which facilitates greater control of execution.

That there is no collapse due to loading, transport and unloading operations on site, and the placing in the formwork using a tower crane.

Immobilisation during concreting, as well as minimum coating.

Structural welded joint:

Electrowelding carried out in the production facilities of ERSI Group can be “structural welding”, that has a joint resistance not less than 50% of the mechanical capacity of the main bar. This allows much higher mechanical resistances, combining the adherence of the bar and that offered by the welding.

Use of structural welding allows reduction of anchor lengths of the bars and avoids in many cases carrying out the standardised anchor bar.

Quality Assurance of the product

As these are reinforcements manufactured in an industrial plant, we assure the highest industry standards.

Traceability System: In the database of each works and for each position of the drawings the following are recorded: data of the casting of all commercial steel used, and specific parameters of the manufacturing processes and operators who have taken part. The reliability of this data is assured using a bar code reading system in all manufacturing operations of the steel used.

Improvements in Health and Safety

Work in the industrial plant facilitates control of the risk and allows implementation of an Occupational Risk Prevention Management System.

Decreasing human resources reduces the number of accidents at work.

Improvements in the environment

The waste generated in industrial facilities is correctly managed.

Manufacture in the industrial plan allows reducing the remains of surplus materials on site and noise pollution in urban areas.

Project documentation

Document management and delivery of technical documentation: proper management of all the information associated with the reinforcements and the raw material from which they came. Transmission to the client of all the documentation so that it can give it to the end customer.

This is a list of the documentation delivered with each shipment:

Guarantee Certificate. It is a document attached to each shipment along with the delivery note.

Reinforcement exploded view drawings. The reinforcement exploded view diagrams describe in detail the products supplied: shape, dimensions, amount, diameter and weight.

The identification label. It relates the elements to the drawing and allows establishing the traceability of the materials used in their manufacture (casting), as well as processes and operators who have taken part.