DESCRIPTION

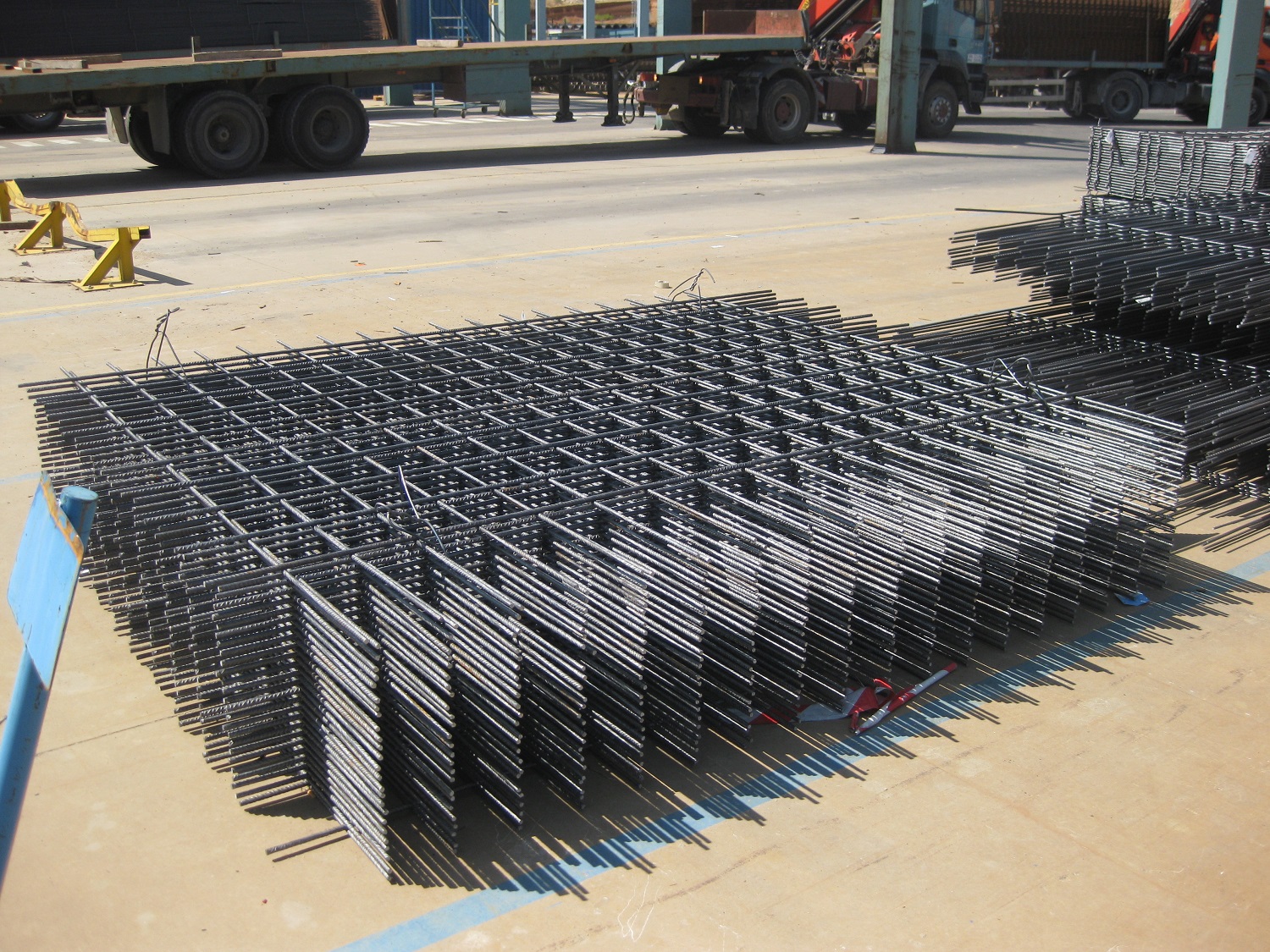

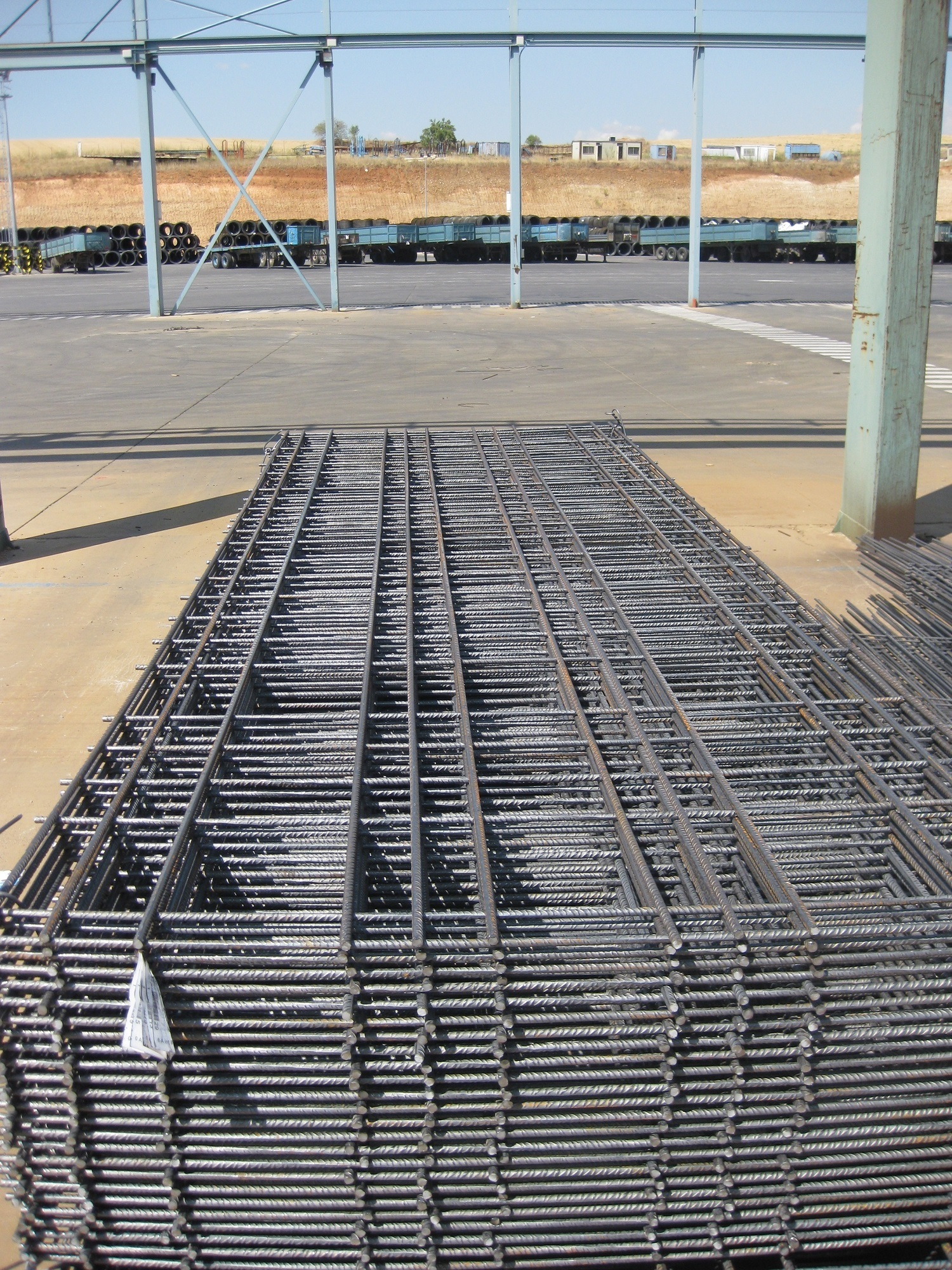

Flat or bent product formed by two systems of elements (bars) that intersect at right angles, whose points of contact are joined by electrowelding.

Manufactured for a specific project. Their dimensions, separation between bars, and use of diameters are adapted to the specific case for which they are designed.

Manufactured in small series or to the unit.

With the possibility of combining diameters, widths and lengths.

Ready to be placed in the formwork and their immediate concreting.

Manufactured in fixed industrial installations and with a voluntary certification system.

Suitable for use in works with execution control.

CHARACTERISTICS

Advantages of made-to-measure panels

Economic

Project execution cost

Allows prefabricating construction elements that are repetitive, therefore, the possibilities of their application are greater.

Reduction of the total cost of the structure. Made-to-measure panels are suitable for the execution control.

Reduction of human resources and suppression of material means for producing and assembling reinforcements on site.

Reduction of deadlines for execution of the structure with new construction methods that replace on site assembly with prefabricated reinforcements.

Reduction of the space needed for the preparation of reinforcements and stockpiling commercial bars, fundamental in urban works.

Use of small lorriesfor delivery to the urban works (contrary to what would be required to provide commercial bars).

The use of structural welding allows reduction of the lengths of the anchors of the bars.

Cost of non-quality during the life of the structure

Industrialisation standardises production, allowing minimum tolerances in measurements and angles, therefore not originating execution costs inherent in excess of tolerance.

Non-quality is the decisive cause of the problems that appear during the life of the concrete structures.

In the case of buildings, risk reduction can provide significant savings in the Guarantee.

Quality assurance

Manufactured according to a Quality Management System.

Plant Quality Director and Quality Coordinator for each work.

Welding and electrowelding: They are used in accordance with the standard.

Traceability System: The following are recorded in the database of each works and for each position of the drawings: data of the casting of all commercial steel used, and specific parameters of the manufacturing processes and operators who have taken part.

Delivery of technical documentation: With regard to the raw material used, to manufacturing processes, and the reinforcements served.

Guarantee Certificate: document enclosed with the delivery note of each shipment.

Check-list, which is enclosed with the previous documents, which indicates the controls carried out in the plant itself on the specific reinforcements of each shipment.

Improvements in Health and Safety

Work in the industrial plant facilitates control of the risk and allows implementation of an occupational risk prevention management system.

Decreasing human resources reduces the number of accidents.

Improvements in the Environment

As a result of production in Fixed Plant.

The waste generated in industrial facilities is correctly managed.

There is a decrease of the remains of leftover materials on site, and of noise pollution in urban areas at the time of the manufacture in the industrial plant.

High Stiffness of the Made-to-Measure Panels

Welded joints ensure:

Separation between the bars as specified in the project, which allows greater control of execution, both on the part of the Building Company and the Works management and of Quality Control.

Avoids its collapse due to loading, transport and unloading operations on site, and the placing in the formwork using a tower crane.

Immobilisation during concreting, as well as minimum coating.

Maximum Flexibility for Adaptation to the Project

The diameters used, separation between bars and anchor and overlap lengths are adapted to the specific case for which they are intended.