The ERSIGROUP en industrial plant in Loughborough, United Kingdom, is a benchmark in customised solutions for the supply, transformation and assembly of corrugated steel in highly complex construction projects. Since its foundation in 2022, this facility has established itself as a strategic partner for construction in the United Kingdom, combining advanced technology, comprehensive traceability and a firm commitment to quality and sustainability.

Technical and Production Capabilities

- With an installed capacity of 5,000 tonnes per month, the plant is organised into two industrial buildings, each measuring 7,700 m², enabling it to offer:

Industrial precision steel cutting and bending. - Assembly of prefabricated elements and reinforcement cages to speed up the construction process.

- Supply and integration of Griptec systems, renowned for their strength and reliability in structural joints.

- Detailed engineering and manufacture of customised meshes and panels, guaranteeing solutions tailored to each project.

Certifications and Quality Standards

The Loughborough plant operates under strict quality, safety and sustainability standards, backed by ISO 9001, ISO 14001, ISO 45001, CHAS and CARES SCS and BES 6001 certifications. These accreditations guarantee that every stage, from raw material to final product, complies with the most demanding technical and regulatory requirements, while also offering customers flexibility to meet specific needs.

Digitised Processes and Complete Traceability

As with the rest of our industrial plants, production planning and control are supported by our own information systems that integrate all phases:

- Production and dispatch scheduling with real-time tracking.

- Digital control of stock and orders, ensuring continuity of the supply chain.

- Automatic generation of delivery notes and 100% guaranteed traceability of each part, from the factory to the delivery of the final product.

Focus on Safety, Deadlines and Optimisation

Our processes in Loughborough are geared towards:

- Reducing manufacturing and on-site assembly times through prefabricated solutions.

- Optimising human and material resources, minimising occupational and environmental risks.

- Ensuring maximum reliability in delivery and on-site execution, with exhaustive control at every stage.

Details

- Name:

- Loughborough

- Location:

- Loughborough, United Kingdom

- Address:

- Falcon Business Park, Meadow Ln, Loughborough LE11 1HL

- .Capacity:

- 30.000 Tn/Year cut & bend - 26.000 Tn/Year Supply

- Land Area:

- 6.000 mts ²

- Warehouse Area:

- 5.400 mts ²

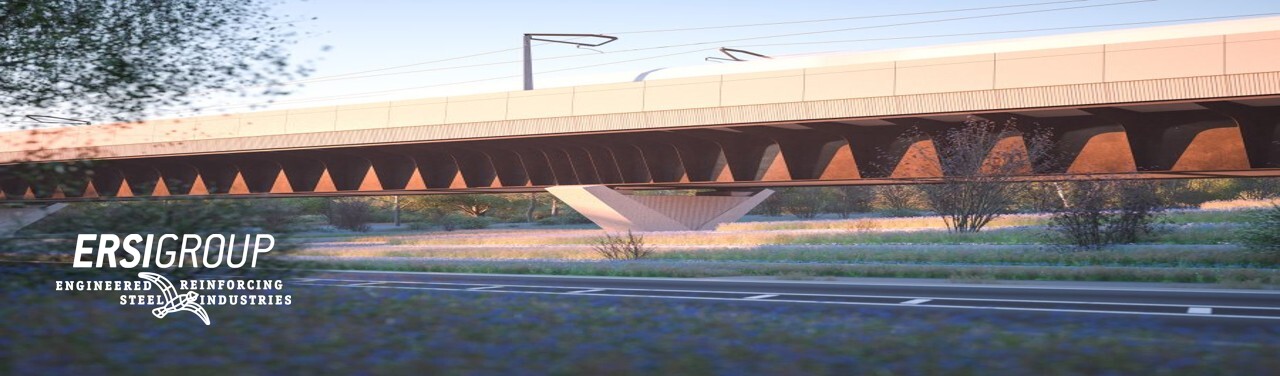

PLANT IMAGES