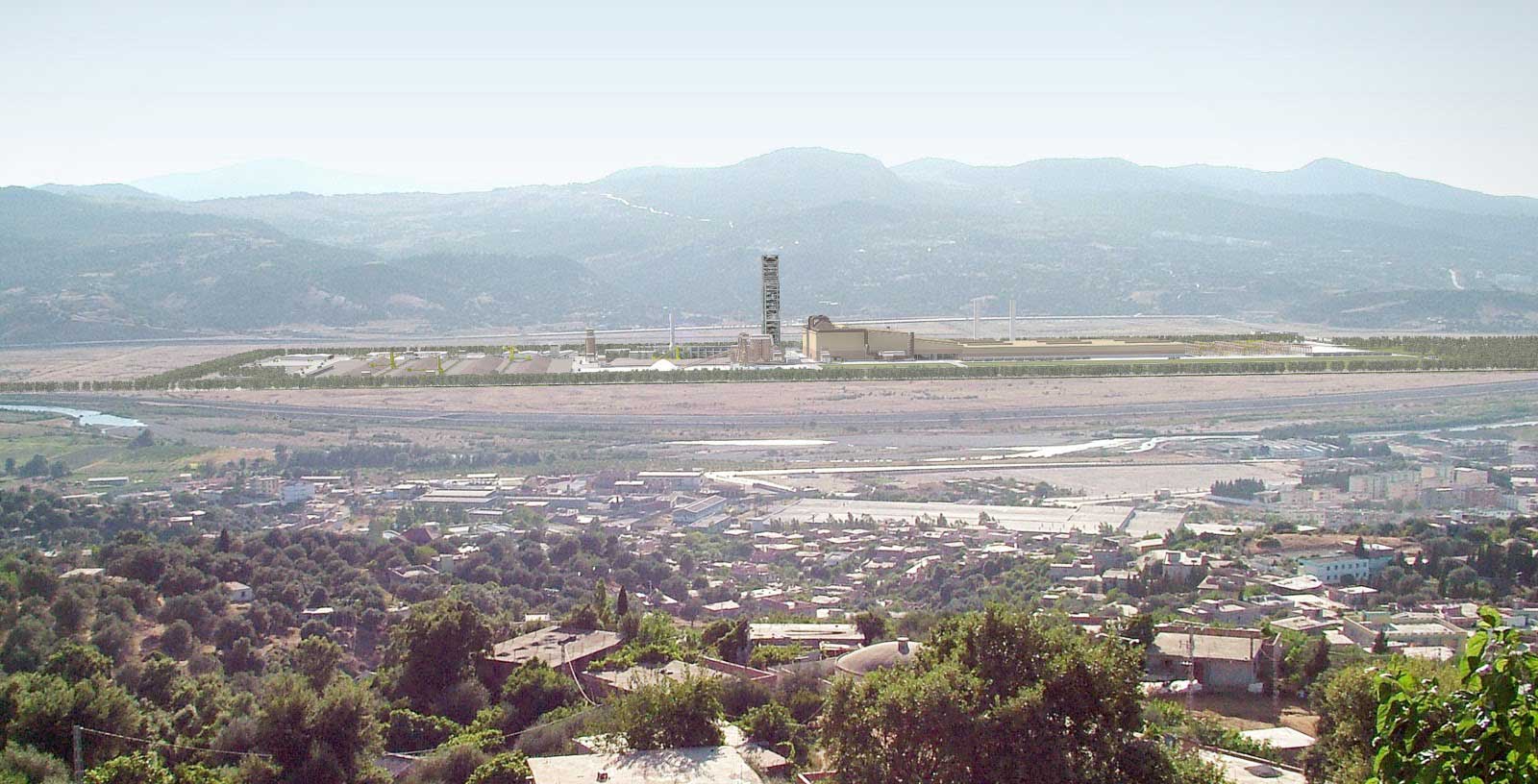

At ERSIGROUP industrial plant in Blida, Algeria, is a benchmark in customised solutions for the supply, transformation and assembly of corrugated steel in highly complex construction projects. Since its foundation in 2004, this facility has established itself as a strategic partner for construction in the country, combining advanced technology, comprehensive traceability and a firm commitment to quality.

Technical and Production Capacities

With an installed capacity of 200,000 tonnes per year, the plant is organised into an industrial warehouse covering 10,500 m², enabling it to offer:

-

- Steel cutting and bending with industrial precision.

- Assembly of prefabricated elements and reinforcement cages to speed up the construction process.

- Supply and integration of coupler systems, renowned for their strength and reliability in structural joints.

- Detailed engineering and manufacture of customised meshes and panels, guaranteeing solutions tailored to each project.

Details

- Name:

- Blida

- Location:

- Blida, Argelia

- Address:

- ZI Ben Boulaid, point Arcelor Mital

- .Capacity:

- 120.000 Tn/Year

- Land Area:

- 96.300 mts ²

- Warehouse Area:

- 22.000 mts ²

Digitised Processes and Complete Traceability

As with the rest of our industrial plants, production planning and control are supported by our own information systems that integrate all phases:

-

- Production and dispatch scheduling with real-time tracking.

- Digital control of stock and orders, ensuring continuity of the supply chain.

- Automatic generation of delivery notes and 100% guaranteed traceability of each piece, from the factory to installation on site.

Focus on Safety, Deadlines and Optimisation

Process design at Loughborough is geared towards:

-

- Reducing manufacturing and assembly times through prefabricated solutions.

- Optimising human and material resources, minimising occupational and environmental risks.

- Ensuring maximum reliability in delivery and on-site execution, with exhaustive control at every stage.